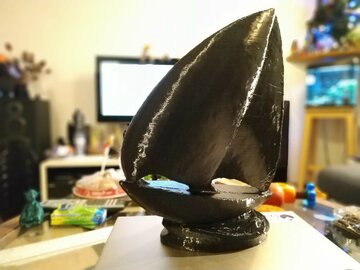

Baby Groot

Awww..

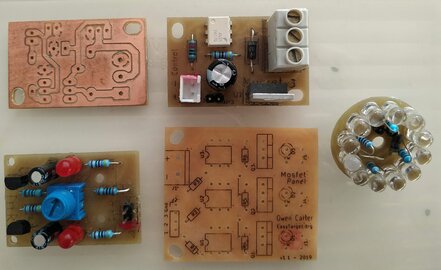

In the distant days of my childhood I was into electronics, making simple circuits and waiting anxiously each month for 'Hobby Electronics' to arrive. I once tried to make a PCB using acid etching, it was a disaster.

These days I've rediscovered the delights of circuitry, but my toolkit is better; the Internet provides research and inspiration, PCB's can be designed with KiCad, and carved on my CNC.

Since I wanted to make things for mysef, I needed to learn some 3D modelling skills.

After a bit of playing around I settled on OpenSCAD as a good tool for my use, with my IT background I'm very comfortable with a 'code' based tool. While there are far more comprehensive Modelling and CAD design tools out there they tend to come at a huge price, or with Freemium strings attached, I appreciate the simplicity of SCAD, and it's ability to make properly dimensioned solid models.

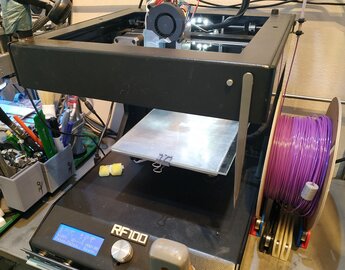

I brought myself a small workshop 3D printer to find out what all the fuss was about, and got sucked in. 'Daisy' is a Renkforce RF100, and has proved a very good purchase. Super reliable, fast, prints very accurately and can handle flex filaments. I've done some simple upgrades to add a part-cooler fan and a heated bed, and the Firmware has had some love. The only real downside is a small print volume.

Having got the bug I wanted something that could print on a grander scale, and fast. The end result is 'Sunflower', a 630x280mm delta printer based on a K280 printer kit from China, and a Duet3D 32bit advanced controller card from the UK.

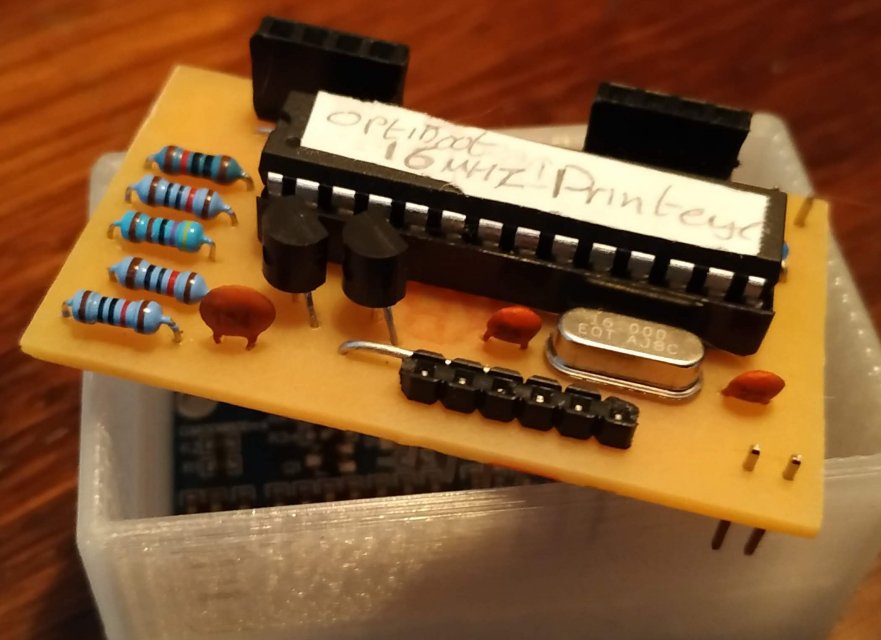

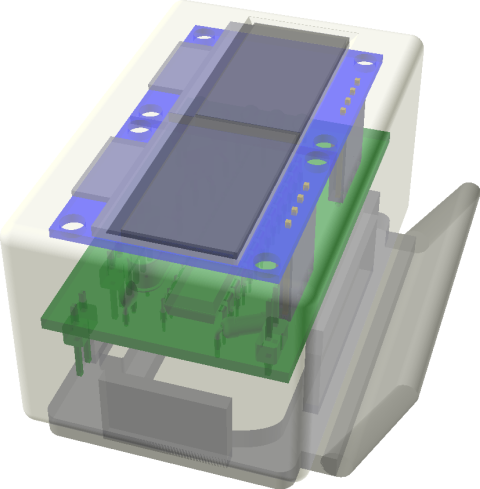

The K280 has proved to be a good basis for this machine, I initially built the kit as supplied, but have been very busy upgrading since then, there are too many things to list, but I am most proud of the PrintEye temperature monitor. Which I designed myself from scratch, combining Software, Hardware and a Case to produce a properly 'finished' unit.

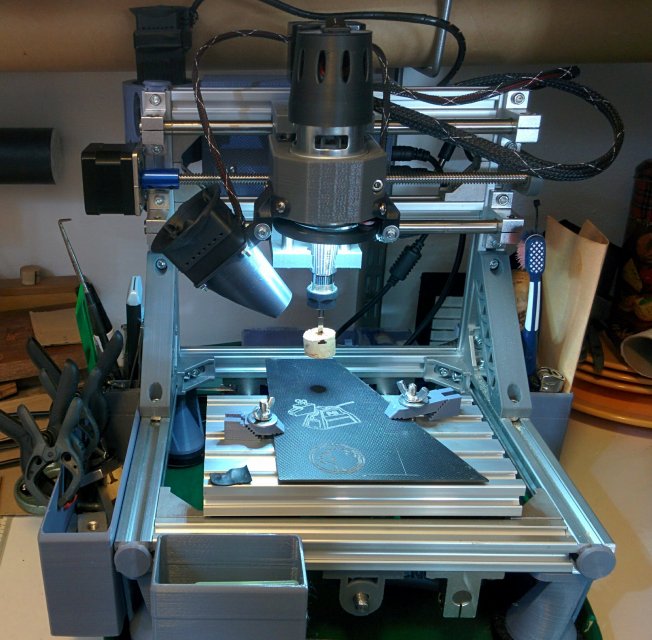

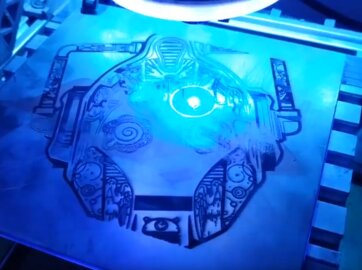

I have a small CNC machine at home, it cuts PCB's, wood and acrylic very well. And the spindle can be easily swapped for a 5.5W laser engraver, which is very effective on wood, leather and anything that burns.

It is controlled by a 32bit wifi-enabled controller card based around the ESP32 microcontroller, this gives me a WebUI and the ability to upload and run jobs from a SD card.

I'm very happy with 'Tulip', in many ways she is more satisfying to use than either of my 3D printers.

Home to all my machines, snug dry and warm in the large storeroom in my apartment. It keeps the printers and CNC out of the way, with storage for filament and supplies. The room has a positive ventilator and a door, so I can run the machines without noise and smell in the rest of my apartment.

There is a supply panel with current leakage protection, a power meter, a 5V Power supply and three relay switched outputs for printers and lights. The 5V supply runs, ahem, four Raspberry Pi's, three USB webcams, and the control boards on all three machines.

One of the Pi's runs both printers through two Isolated OctoPrint instances, and also has three GPIO controled relays which turn the 3D printers fully off when not in use. Another runs two of the webcams and has a wired network connection to my router so it can, in turn, provide a dedicated Wireless hotspot for the room.

Some of the things I have made, mostly other peoples designs

Awww..

All my own work, a temperature display for my delta printer

A sculpture scan from 'scan the world', which I printed at a decent size for my parents garden, done in carbon-black PETG for durability, this was really nice to handle

My trusty Renkforce RF100, a very reliable and accurate workhorse, not as sexy as the delta printer but I love her all the same.

A print-in-place Bird nester that unfolds once printed

Cutting the reflective material off the back of a mirror tile, the effect from the front is really pleasing.

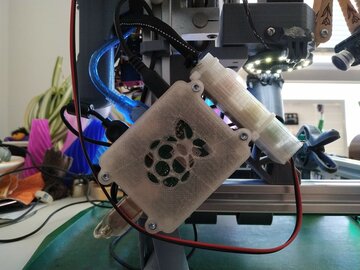

A case for a Raspberry Pi 3A+, plus a ittle box for some buttons etc.

Playing with the sizes my printers can achieve

Small status monitors for my sittingroom; ESP32 based with a OLED display, they connect to the Octopritn API over my wifi and show me print statuses without having to dig my phone out

My cat is not impressed with my new Christmas ornament

A very handy piece of apparatus for checking my work, but came with a useless, wobbly, 'stand'; so I made a better one.

Experimenting with Objects from the 'Scan the world' collection, and fancy filamants

Most of the part cooler designs I've gone through since getting my K280 working

PCB cutting on the CNC.

Are particularly good at this sort of Spiral vase, use a thick nozzle and translucent filamant and the results are great